Ensuring the quality of a wheelchair quick release pin axle is crucial for safety, durability, and functionality. Here’s a step-by-step guide to help you evaluate the quality of these components:

1. Inspect Physical Condition

a. Visual Inspection:

Surface Finish: Check for any visible defects such as rust, corrosion, cracks, or scratches on the pin and axle. The surface should be smooth and free from any damage.

Uniformity: Ensure that both the pin and axle are uniformly manufactured. Look for any irregularities in shape or size that could indicate poor quality.

b. Fit and Alignment:

Pin Fit: Insert the pin into the axle and wheel hub. The pin should fit snugly without excessive play. It should engage and disengage smoothly.

Axle Alignment: Check that the axle is straight and properly aligned. Any bending or warping can affect performance and safety.

2. Measure and Verify Specifications

a. Dimensions:

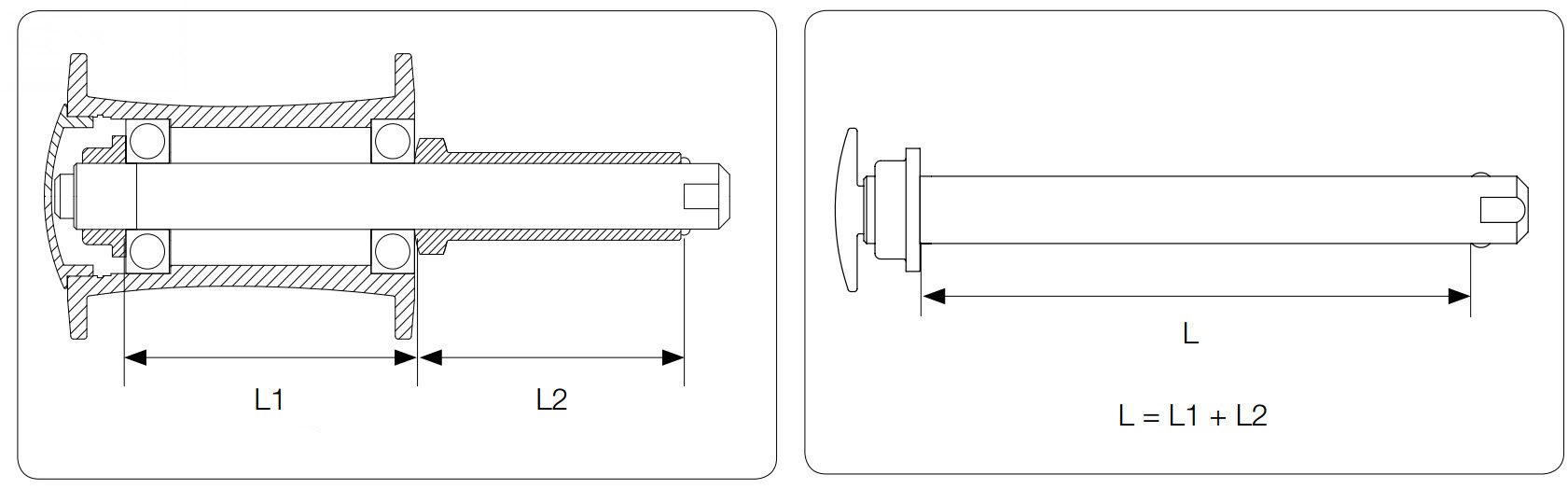

Pin and Axle Measurements: Use a caliper or micrometer to measure the diameter and length of both the pin and axle. Compare these measurements with the specifications provided by the manufacturer or the required standards.

Tolerance Levels: Ensure that the measurements fall within acceptable tolerance levels. Manufacturing defects can cause parts to be out of specification.

b. Functional Testing:

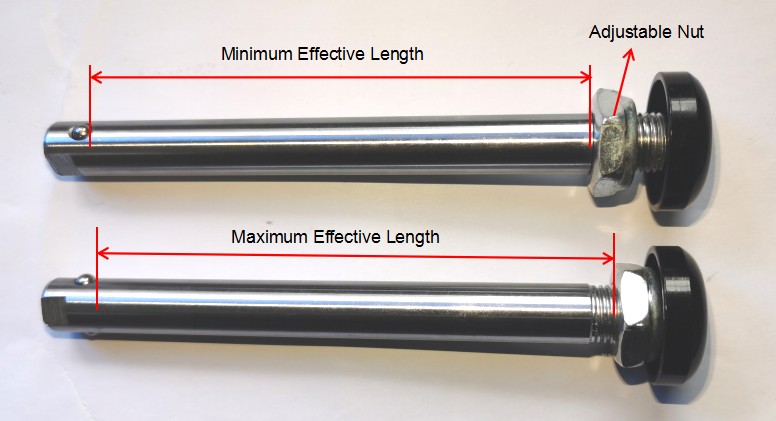

Quick Release Mechanism: Test the quick release mechanism by engaging and disengaging the pin. It should lock securely in place and release easily without any hitches.

Load Testing: Apply a moderate load to the pin and axle to check for stability and durability. The pin and axle should hold up under typical usage conditions without bending or deforming.

3. Material Quality Assessment

a. Material Verification:

Material Type: Confirm that the pin and axle are made from high-quality materials, such as stainless steel or aluminum, known for their strength and durability.

Material Finish: Look for any signs of poor material quality, such as rough finishes or inconsistencies that could affect performance.

b. Corrosion Resistance:

Test for Corrosion: Check for any signs of corrosion, especially if the pin and axle are used in humid or wet environments. Quality components should have a protective coating to resist corrosion.

4. Evaluate Workmanship

a. Precision:

Manufacturing Accuracy: Ensure that the pin and axle are manufactured with precision. High-quality components should have tight tolerances and minimal variation.

Consistency: Check for consistency in workmanship. High-quality parts should exhibit consistent quality across different units.

b. Machining and Finish:

Edge and Surface Quality: Inspect the edges and surfaces for smoothness and proper finishing. Sharp edges or rough surfaces can cause wear and affect functionality.

5. Verify Manufacturer and Standards

a. Manufacturer Reputation:

Brand Reliability: Choose parts from reputable manufacturers known for high-quality wheelchair components. Research the manufacturer’s history and reviews.

b. Compliance with Standards:

Industry Standards: Ensure that the pin and axle comply with relevant industry standards or regulations. This includes safety and performance standards specific to wheelchair components.

6. Perform Routine Maintenance Checks

a. Regular Inspections:

Frequent Checks: Regularly inspect the pin and axle for signs of wear, damage, or performance issues. Address any issues promptly to maintain safety and functionality.

Lubrication: Apply appropriate lubrication to moving parts to prevent wear and ensure smooth operation.

Summary

Checking the quality of a wheelchair quick release pin axle involves inspecting physical condition, measuring and verifying specifications, assessing material quality, evaluating workmanship, and ensuring manufacturer reliability. By conducting thorough inspections and tests, you can ensure that the components are safe, durable, and functional. Regular maintenance and attention to detail will further contribute to the overall quality and longevity of the wheelchair’s quick release system.

Comments

Post a Comment