To confirm the size of a wheelchair quick release axle, you need to accurately measure both the axle itself and the components it interfaces with. Here’s a step-by-step guide to ensure you get the correct size:

Tools Needed

Caliper or Tape Measure: For measuring diameters and lengths.

Wrench or Tool Kit: If you need to remove the axle.

Paper and Pen: For recording measurements.

Step-by-Step Guide

1. Prepare for Measurement

Stabilize the Wheelchair: Ensure the wheelchair is on a stable surface, and the wheels are locked to prevent movement.

Remove the Axle: If the axle is currently installed, release it by operating the quick release mechanism (usually a lever or knob) and carefully remove the axle from the wheel hub and frame.

2. Measure the Axle Dimensions

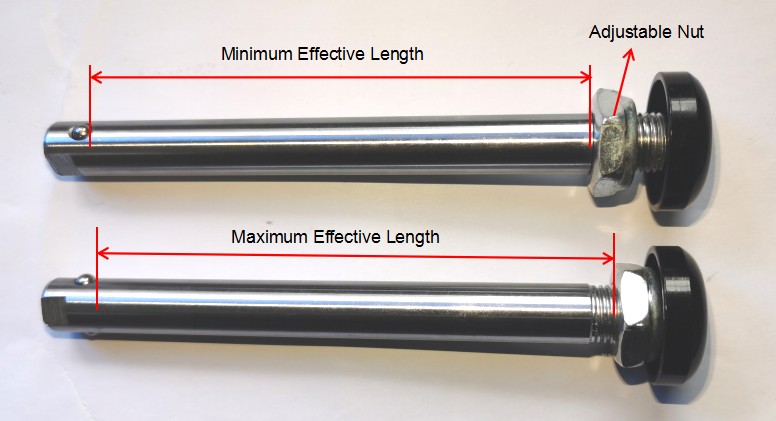

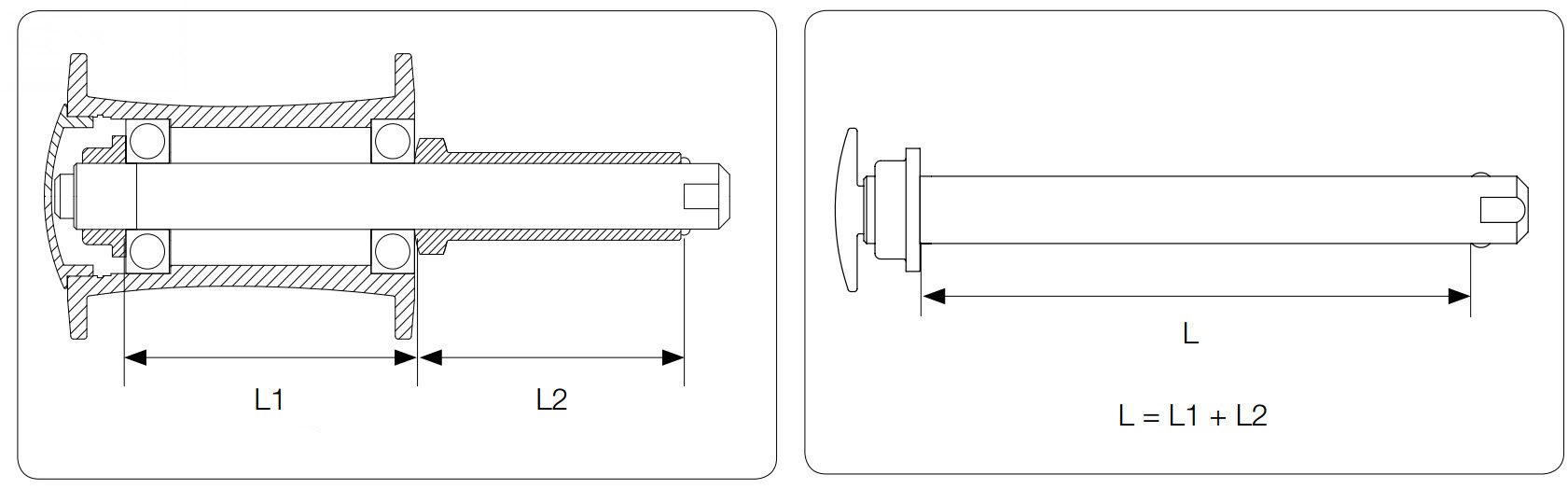

Measure the Axle Length

Lay the Axle Flat: Place the axle on a flat surface.

Measure the Length: Use a tape measure or caliper to measure from one end of the axle to the other. Ensure you measure along the length of the axle, not diagonally.

Measure the Diameter of the Axle Shaft

Use a Caliper: Measure the diameter of the axle shaft. Ensure the caliper is perpendicular to the shaft for an accurate reading.

Record the Diameter: Write down the diameter measurement.

Measure the End Caps (if applicable)

Measure Diameter and Length: If the axle has end caps, measure their diameter and length as well. These measurements are crucial for compatibility with the wheelchair frame and wheel hub.

3. Measure the Wheel Hub Dimensions

Measure the Inner Diameter of the Wheel Hub

Use a Caliper: Measure the inner diameter of the wheel hub where the axle fits. This ensures the axle will fit properly within the hub.

Measure the Hub Width

Measure the Width of the Hub: This is the distance between the inner surfaces of the wheel hub. It helps to confirm that the axle length will work with the wheel hub.

4. Confirm Compatibility

Compare Axle Diameter with Hub Diameter

Ensure that the diameter of the axle matches the inner diameter of the wheel hub. The axle should fit snugly without excessive play.

Confirm Axle Length Relative to Hub Width

The wheelchair quick release pin should extend slightly beyond the wheel hub when installed. Check that the axle length is appropriate for the width of the hub.

Check Quick Release Mechanism

Ensure the quick release mechanism on the axle is compatible with the wheelchair’s frame and wheel hub. Different mechanisms might require specific axle designs.

5. Additional Considerations

Consult Manufacturer Specifications

Refer to the wheelchair manufacturer’s specifications for exact axle dimensions and recommendations for compatible parts.

Test Fit

Insert the axle into the wheel hub and frame to check for proper fit. Ensure the axle locks securely and the wheel rotates smoothly.

Seek Professional Advice

If you have any doubts or difficulties, consult with a professional or a wheelchair technician for assistance.

By following these steps, you can accurately confirm the size of your wheelchair quick release axle and ensure it fits properly.

Comments

Post a Comment